We’ve had our Kyocera FS-1030D printer for almost a decade & it wasn’t new when we received it. It’s all that we need in a printer though, good quality print (Although only monochrome), networked & duplexed, we’ve also got more spare toner for it than you can shake a stick at.

Last week while printing pages started coming out misaligned vertically by variying amounts. I’ve recently upgraded our server so my first thought was driver compatability with the new operating system. I installed the printer onto a Windows 7 VM & tested but the results were the same, so I thought it was probably a hardware issue.

Searching on the internet I found this is a fairly common problem with the FS-1020 which is a very similar printer to the FS-1030D. The issue is with 3 solenoids on the right hand side of the machine. When originally installed these solenoids have small pieces of foam stuck to the levers to suppress the noise they make when activating. Over the years this foam deteriorates & becomes sticky, slightly delaying the paper feed mechanism timing, which messes with the print positioning.

I downloaded the printer service manual from the Kyocera site, although the disassembly was pretty straightforward: Remove the printers top cover by taking out the 2 screws on the top, take off the little access hatch on the rear of the right side & then remove the right side panel. This panel is held on by clips that you can disengage using a small screwdriver, there are a couple in the front and 3 or 4 across the top.

After removing the cover you’ll see a circuit board screwed to the upper left side fixed by 3 screws and having 12 cables connected to it. We disconnected the cables & unscrewed the board to remove it. Under the board was a white cover held on by a couple of screws, removing this revealed the 3 solenoids.

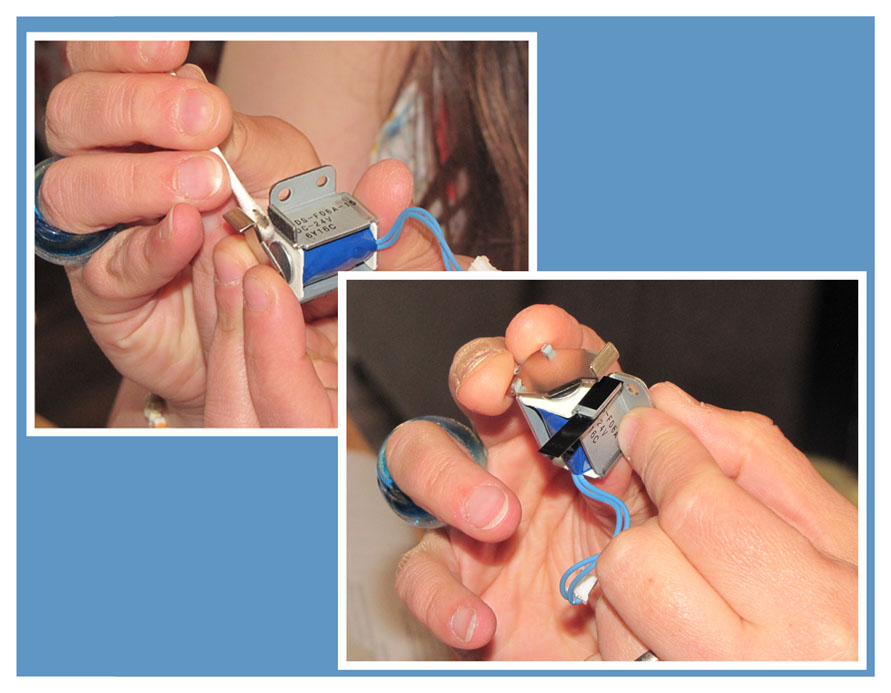

We disconnected & removed the solenoids one at a time, cleaning off the sticky foam with alcohol & cotton buds, then wrapping electrical tape around the metal as a replacement for the foam. Be careful you don’t use too much as this will stop the solenoid working correctly, we just wrapped it around once or twice.

After reassembling the printer the issue was fixed & We’re now looking forward to the next decade of FS-1030D use.